HB Crates

more product safety, less impact on the planet

HB’s returnable plastic crates follow the product throughout the entire supply chain, providing protection, sustainability, and smart logistics.

Lightweight, collapsible, and up to four times more resistant than cardboard, they ensure protection and standardized transport — from the distribution center to the point of sale.

All asset management is handled by HB, with control, traceability, and a logistics network that serves different regions with agility and precision.

Reduces losses by keeping products better protected.

optimizes space during transport and at the distribution center, with up to 80% less volume on return.

Our crates can be displayed directly at the point of sale.

Lowers costs and environmental impact, aligned with the circular economy.

Strategic ventilation that supports preservation, along with lightweight and smart stacking for easy handling in the field, during transport, and at the point of sale.

Sturdy structure and stable stacking prevent breakage during transport, ensuring eggs arrive intact at retail. Smooth surface for easy sanitization, with continuous reuse, traceability, and cost savings.

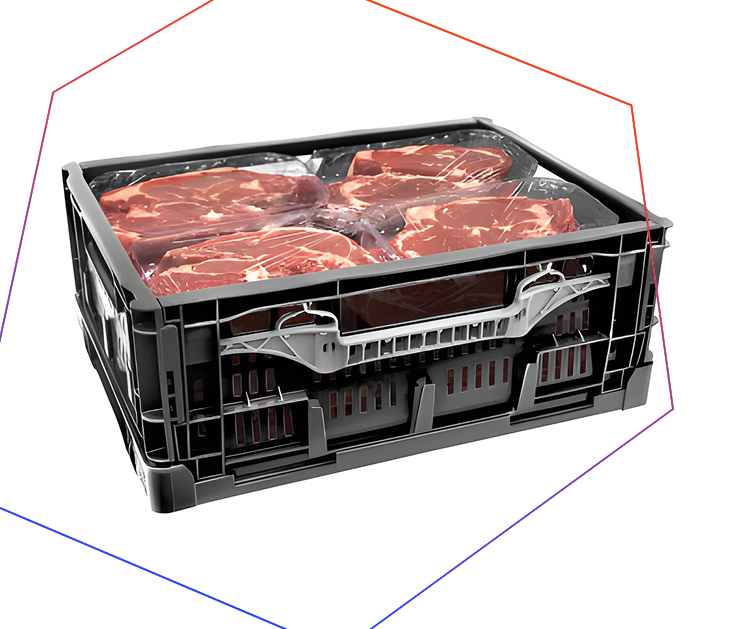

Crates with high durability, ventilation, and easy sanitization — ideal for preserving product integrity throughout the cold chain for fresh, frozen, or vacuum-packed meats. They help maintain optimal temperature, ensure product quality, support food safety, and reduce losses.

HBpooling crates follow products from the distribution center to the point of sale and can be used as display units, ensuring speed and product preservation all the way to the final consumer.

Our process complies with state sanitary regulations, ensuring that crates circulate between regions with full compliance and logistical efficiency.